|

Your Plasma Torch, Consumables and Increasing Their Life

A quick guide to Maintaining your torch

|

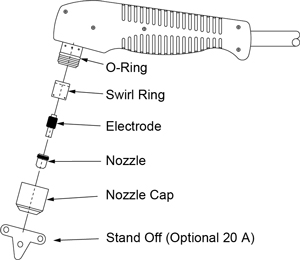

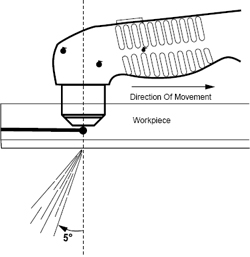

TORCH CONSUMABLE PARTS

All the parts on the end of the torch (consumables) are replaceable by hand with no tools required. Unscrew the nozzle cap and access is obtained to the nozzle, electrode, swirl ring, and o-ring.See Figure 10.

REPLACING CONSUMABLE PARTS

During the cutting process, the parts on the end of the torch are slowly consumed. To prevent premature consumption of some torch parts and to prevent damage to the torch itself, it is necessary to replace the consumable parts in a timely manner.

Note:

Consumable life estimates are approximations made for mild steel, under ideal conditions only. Your actual times may vary. Variations in materials and user technique can add to or diminish from consumable life. When cutting aluminum, expect about one-half the nozzle and electrode life.

|

br/> br/>

Figure 10. Torch Parts (Consumables)

|

NOZZLE

The 50 Amp plasma cutter consumables have an expected life of up to 30 minutes of actual cutting time (time that the arc is established). Consumable life may be greatly reduced when cutting thicker materials. The 20 Amp cutter consumables have an expected life of up to 45 minutes

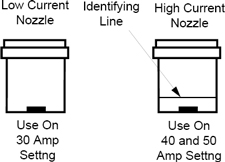

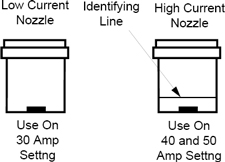

of actual cutting time (time that the arc is established). As cutting time accumulates, the hole in the nozzle becomes larger and distorted and will cause the cut to wander. Untimely replacement can lead to shorter electrode life expectancy. The 50 Amp cutters, only, have a high current nozzle and low current nozzle (see Figure 11). One nozzle is best suited for materials that require higher amperage settings. The other is best thinner materials, that require lower amperage settings.

|

Figure 11.High Current & Low Current Nozzles

|

ELECTRODE

The electrode has a life expectancy of approximately 45 minutes of actual cutting time. As it deteriorates, the arc will become weaker and break up of the arc may occur. Untimely replacement can lead to shorter swirl ring life expectancy.

SWIRL RING

The swirl ring has a life expectancy of approximately 3 hours and 30 minutes of actual cutting time. It needs to be replaced when visual evidence of cracks, chips, or burn spots begin to occur.

NOZZLE CAP

The nozzle cap should be replaced when any cracks or any burn through holes begin to develop. always inspect the swirl ring when replacing a nozzle cap and replace both, if necessary.

TORCH STAND OFF

The torch stand off allows you to set the spacing between the nozzle and the work piece to be cut. It attaches to the nozzle cap and should be adjusted so the gap between the nozzle and the work is 1/16 inch. This gap is extremely important for clean cuts in thicker materials when cutting at the 40 or 50 amp setting. The torch stand off is also useful for following patterns or guides when cutting.

O-RING

The o-ring is very important to cutting performance and must be replaced when it flattens or takes a physical set due to pressure. To extend o-ring life, lubricate it with the silicone lubricant (packed with your cutter) every second or third time that the nozzle cap is removed. The lubricant should be applied only to the o-ring after it is in place on the torch. Be careful not to get lubricant on any of the other consumable parts or they may be destroyed. Always wipe excess lubricant from fingers before handling any of the other consumable parts.

HINTS FOR INCREASING LIFE OF CONSUMABLES

-

Use clean, dry, oil-free compressed air only.

-

Establish and maintain a good electrical connection with the ground clamp to the material being cut.

-

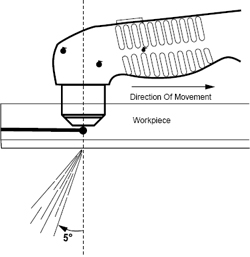

Establish and maintain a consistent distance of about 1/16 inch between the material being cut and the torch nozzle.

-

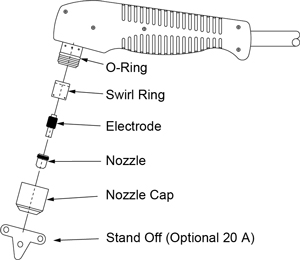

Establish and maintain proper movement speed. The optimum torch movement speed for maximum consumable life is that which results in the main shower of sparks trailing approximately 5 degrees behind the main axis of the torch as depicted in Figure 12.

|

|

|

Figure 12. Torch Movement

|

|

br/>

br/>